High-performance Plate Heat Exchanger Units, Enhance Heat Transfer Efficiency

1. High-efficiency Heat Exchange Performance

2. Compact Structure

3. Adjustable Heat Transfer Capacity

4. Highly Efficient Heat Recovery

5. Detachable and Cleanable

6. Adapt to a Variety of Working Conditions

7. Energy Saving and Environmental Protection

8. Small Footprint, Easy Installation

Plate heat exchanger unit is a highly efficient and compact heat exchange equipment widely used in various industrial and commercial fields. It carries out heat transfer through the stacked structure of multiple thin metal plates to realize heat exchange between two fluids. Plate heat exchanger units have become the preferred heat exchange equipment for a wide range of industrial and energy applications due to their compact structure, high heat exchange efficiency, and good maintainability.

OVERVIEW

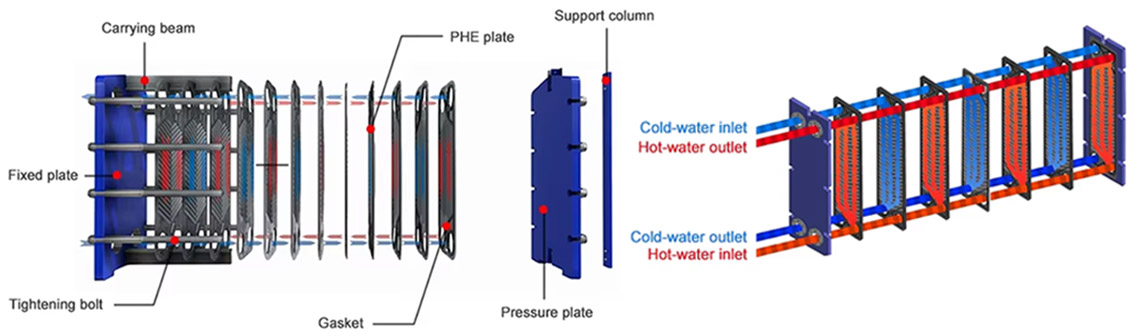

The plate heat exchanger unit consists of a number of corrugated metal plates (usually stainless steel or titanium alloy) secured into a compact modular structure by means of gaskets, welds or mechanical connections. The heat medium flows through the flow paths between these plates and heat is exchanged by heat conduction and convection. A common plate heat exchanger unit consists of the following major components:

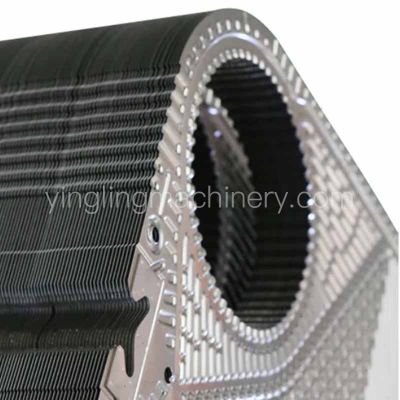

Plates: The surface of each plate has a corrugated structure that enhances fluid turbulence and increases heat exchange. The flow paths between the plates are sealed by gaskets or welds to ensure that the fluids do not mix.

Gasket: Used to seal the contact surface between the plates to prevent mixing of the two fluids. Gaskets are usually made of high-temperature, corrosion-resistant rubber or PTFE (polytetrafluoroethylene).

Frames and Compression Devices: Frames, usually made of steel, are used to hold the plates in place and apply the necessary pressure to maintain tight contact between the plates. Compression devices help ensure a tight seal between the plates to avoid leakage.

Piping and Connectors: Used to connect the heat exchanger unit to the fluid piping to ensure the flow of fluid into and out of the heat exchanger.

Support: supports the entire structure of the plate heat exchanger to ensure stable operation of the unit.

Features

1. High-efficiency Heat Exchange Performance

The plate heat exchanger increases the turbulence effect of the fluid through its corrugated structure, which makes the heat transfer coefficient increase, thus increasing the heat exchange efficiency. Compared with the traditional shell-and-tube heat exchanger, the plate heat exchanger has a higher efficiency per unit heat exchange area, and is able to provide greater heat exchange capacity in a smaller volume.

2. Compact Structure

The design of the plate heat exchanger makes it very compact with a small footprint. With the same heat transfer requirements, plate heat exchangers are usually smaller in size and weight than other types of heat exchangers, making them suitable for locations with limited space.

3. Adjustable Heat Transfer Capacity

Plate heat exchangers are able to flexibly adjust the heat exchange capacity by increasing or decreasing the number of plates. This modular design allows the plate heat exchanger to be customized according to the actual demand, both to meet the needs of low load, but also to cope with high load conditions.

4. Highly Efficient Heat Recovery

In some applications, plate heat exchangers can be used in waste heat recovery systems, which help reduce energy consumption and improve energy utilization. For example, in industrial production, the waste heat of hot exhaust gases or cooling water can be recovered by plate heat exchanger, reducing overall energy consumption.

5. Detachable and Cleanable

Detachable plate heat exchangers are structurally designed to be easily disassembled, cleaned and maintained, which is critical for handling fluids containing contaminants or sediments (e.g., in food processing, chemical and other industries). Regular cleaning and maintenance can ensure the efficient operation of the equipment.

6. Adapt to a Variety of Working Conditions

Plate heat exchanger for different temperatures, pressures, flow rates and media conditions of heat exchange, and can be in high temperature, high pressure, low temperature and corrosive media and other complex operating conditions. Different types of plate heat exchanger (such as welded, removable, sealed, etc.) can be selected according to the needs of a very strong adaptability.

7. Energy Saving and Environmental Protection

Due to its efficient heat exchange capacity, plate heat exchanger can effectively reduce energy loss, help industrial and commercial enterprises to reduce energy consumption, thereby reducing operating costs and achieve energy saving and environmental protection effect.

8. Small Footprint, Easy Installation

Compared with other large heat exchanger equipment (such as shell and tube heat exchanger), plate heat exchanger covers a small area, and can usually be installed directly in the factory, reducing the need for space, easy to install and maintain.

Application Fields

Due to its diverse characteristics, plate heat exchanger is widely used in many industries, including but not limited to the following areas:

Chemical Industry: for reactor cooling, solution heating, steam heat transfer, etc.

Food and Beverage Industry: for hot water sterilization, food heating, cooling and other processes.

Air-conditioning and Refrigeration Industry: widely used in air-conditioning systems and refrigeration systems as heat pumps, condensers, evaporators and other components.

Energy Industry: used for waste heat recovery, heat exchange, cooling in oil refining, power plant, nuclear power plant and other fields.

Pharmaceutical Industry: used for heating, cooling and heat exchange in the process of drug production.

Seawater Desalination: used for heat exchange in the process of seawater desalination to improve desalination efficiency.

Plate heat exchanger units have become important equipment in industrial applications due to their high efficiency heat exchange, compact structure, flexible adjustment capability and good maintainability. They can effectively improve energy utilization, reduce operating costs, adapt to a variety of complex working conditions, and are widely used in a variety of fields. Whether in the chemical, food processing, air conditioning and refrigeration or energy industries, plate heat exchanger units are ideal for energy saving and efficient heat transfer.