High-Pressure Durable Plates for Plate Heat Exchanger, Enhancing System Stability

1.High heat transfer efficiency

2.The heat exchange area is easy to change

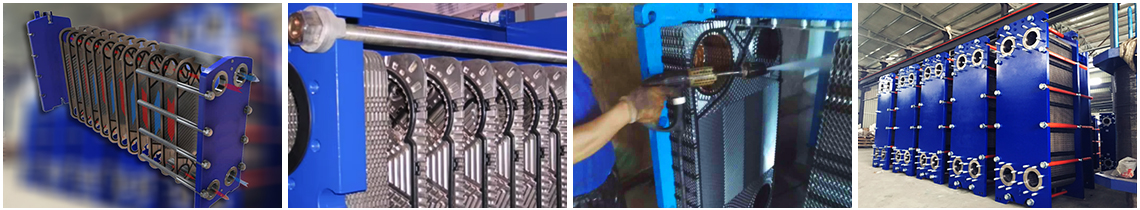

3.Easy to disassemble for cleaning

4.Saves resources

Overview

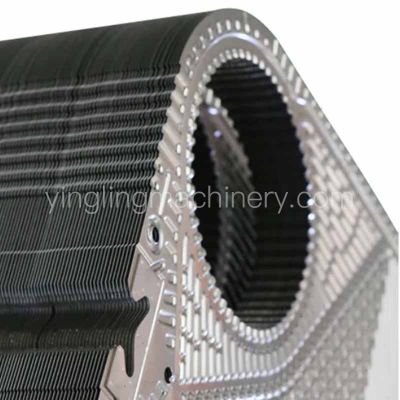

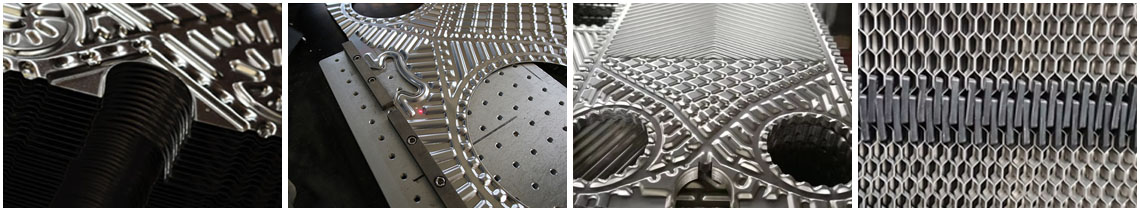

Plates are the core component of a plate heat exchanger and are typically made of stainless steel, titanium or other corrosion-resistant materials. Specific flow paths are designed into each plate to direct fluid flow and enhance heat exchange.

Features

1.High heat transfer efficiency

Fluid enters the plate heat exchanger and passes through the inlet pipe into the first plate group.

2.The heat exchange area is easy to change

Each set of plates increases the efficiency of heat exchange because the fluid has more time to contact the plates and exchange heat.

3.Easy to disassemble for cleaning

This ease of maintenance results in longer equipment life and reduced maintenance.

4.Saves resources

Due to their efficient heat transfer and compact design, gasket heat exchangers require less cooling water and footprint, reducing wasted resources.

Application Fields

1. Refrigeration: used as condenser and evaporator;

2. HVAC: intermediate heat exchanger used with boilers, intermediate heat exchanger in high-rise buildings, etc.

3. Chemical industry: soda ash industry, ammonia synthesis, alcohol fermentation, resin synthesis cooling, etc.

4. Metallurgical industry: heating or cooling of aluminate mother liquor, cooling of steel making process, etc.

5. Machinery industry: cooling of various quenching liquids, cooling of lubricating oil for speed reducer, etc.

6. Power industry: high-voltage transformer oil cooling, generator bearing oil cooling, etc.

7. Paper industry: bleaching process heat recovery, heating pulp washing, etc.

8. Textile industry: alkali solution cooling viscose silk, boiling nitrocellulose cooling, etc.

9. Food industry: juice sterilization and cooling, heating and cooling of animal and vegetable oils, etc.

10. Fats and oils processing: soap-based atmospheric pressure drying, various processes of liquid heating or cooling;

11. Centralized heating: waste heat from thermal power plants for district heating, heating bath water;

12. Others: petroleum, medicine, ships, desalination, geothermal use.