Versatile Brazed Plate Heat Exchanger for Various Applications

1. High efficiency.

2. Low energy consumption.

3. Low cost.

4. Corrosion resistance.

5. Easy maintenance.

Product Description

Overview

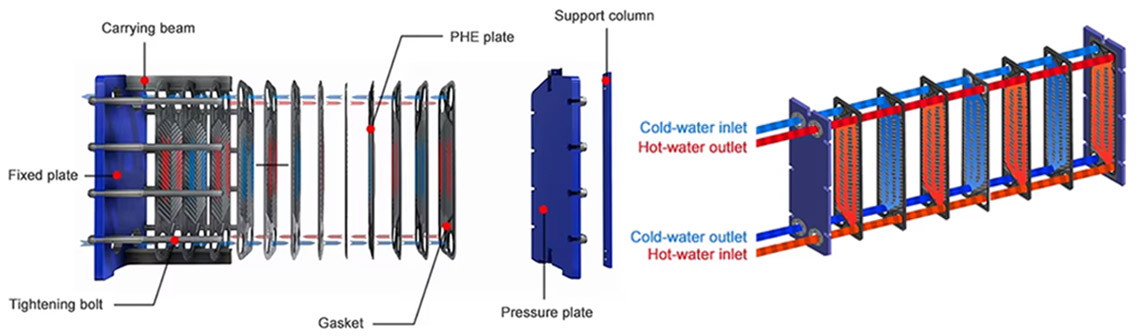

Plate heat exchanger is a highly efficient heat exchange equipment, which consists of multiple plates stacked on top of each other to form multiple fluid channels. It exchanges heat between the plates by fluids of different temperatures, thus realizing the transfer of heat energy.

Features

1. High efficiency: the large area of heat exchange surface and good fluid disturbance improve the heat exchange efficiency.

2. low energy consumption: on the basis of high efficiency, it can complete heat exchange with low energy consumption, reducing operating costs.

3. Compact design: occupies little space, suitable for applications with limited space.

4. Easy maintenance: parts can be easily disassembled, cleaned and replaced, making maintenance work simple and efficient.

5. Flexibility: the number and arrangement of plates can be adjusted according to the actual demand, adapting to different working conditions and fluids.

6. Corrosion resistance: corrosion-resistant materials are selected to adapt to a variety of chemical fluids to ensure long-term stable operation.

7. low fouling rate: fluid flow and plate design effectively reduce fouling phenomenon, improve the service life of the heat exchanger.

8. Easy to clean: designed for easy cleaning, to ensure that the heat exchange efficiency is not affected, easy maintenance.

9. Low cost: relative to other types of heat exchangers, low manufacturing and maintenance costs, good economy.

Application Fields

1. Refrigeration: used as condenser and evaporator;

2. HVAC: intermediate heat exchanger used with boilers, intermediate heat exchanger in high-rise buildings, etc.

3. Chemical industry: soda ash industry, ammonia synthesis, alcohol fermentation, resin synthesis cooling, etc.

4. Metallurgical industry: heating or cooling of aluminate mother liquor, cooling of steel making process, etc.

5. Machinery industry: cooling of various quenching liquids, cooling of lubricating oil for speed reducer, etc.

6. Power industry: high-voltage transformer oil cooling, generator bearing oil cooling, etc.

7. Paper industry: bleaching process heat recovery, heating pulp washing, etc.

8. Textile industry: alkali solution cooling viscose silk, boiling nitrocellulose cooling, etc.

9. Food industry: juice sterilization and cooling, heating and cooling of animal and vegetable oils, etc.

10. Fats and oils processing: soap-based atmospheric pressure drying, various processes of liquid heating or cooling;

11. Centralized heating: waste heat from thermal power plants for district heating, heating bath water;

12. Others: petroleum, medicine, ships, desalination, geothermal use.